AusGroup played a key project management role providing support to the client and operator which included the preplanning,

scheduling, procurement and HAZID risk assessments, engineering, and multi-disciplined IRATA Rope Access Technicians for a 3-phase execution process.

PHASE 1 – NDT campaign to conduct a structural integrity report.

PHASE 2 – Offshore removal preparation. Prepare the facility for removal. Weld and NDT lift points and complete lift study

requirements.

PHASE 3A – Offshore removal. Multi-disciplined rope access rigging and BMW crew removed the above sea production

facility.

PHASE 3B – Offshore removal. Specialised welding and boilermaker team sea fastened the removed topside facility and removed subsea structure to a transport barge for ocean freight.

Continuous Improvement Initiatives

Innovation 1

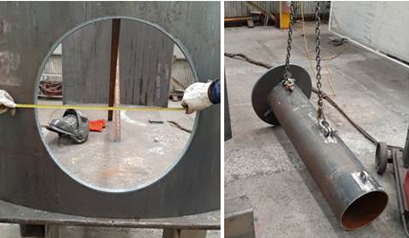

Design of a multi-functional device called a ‘Lifting and Cutting Trunnion’. This cleanly cut a 600mm symmetrical section of steel on each opposing side of the main caisson. The custom made lifting and cutting trunnion created a precision and guaranteed clean cut, eliminated risk of dropped objects and manual handling.

Innovation 2

Design and engineering of a safe working platform, with an easy fit bracket system. This improved safety for Rope Access Boilermakers and improved their working tolerance on the ropes. Overall, this saved time and increased project efficiency and

cost effectiveness.

Innovation 3

Use of the Pneumatic Clamshell Cutting System to mitigate the risk of igniting residual volatile hydrocarbons when cutting into the fuel riser. Due to hydrocarbons being present AusGroup proposed Clam Shell Cutting, which is a dry cutting device that is a no spark and no flame. This allowed the AusGroup teams to safely separate it from the subsea section to the production deck.

CASE STUDIES

Integrated Turnaround Maintenance Project for LNG Asset

The sixth in planned turnaround maintenance programs for a key LNG operator in the North West…

INPEX-operated Ichthys LNG Project – Rope Access Trade Services

MAS Australasia was awarded a contract from Clough Projects International to supply rope access trade services…

GLNG Maintenance – Scaffold Supply and Design

MAS supported the project by providing scaffolding material directly to UGL, who are undertaking the maintenance…